AEM Quickly Adapts for Clients’ Needs

When inventory shortages risked shutting down an entire production line, AEM responded to a client's needs and turned the project around in 24 hours.

Technology is terrific - except when it’s not.

A manufacturer of industrial electrical products uses a massive ERP system to keep track of what parts they have in their inventory. But every so often, when they go to pull a part from their stock, it’s not there. The situation is dire: they either get the part quickly or risk shutting down the entire production line.

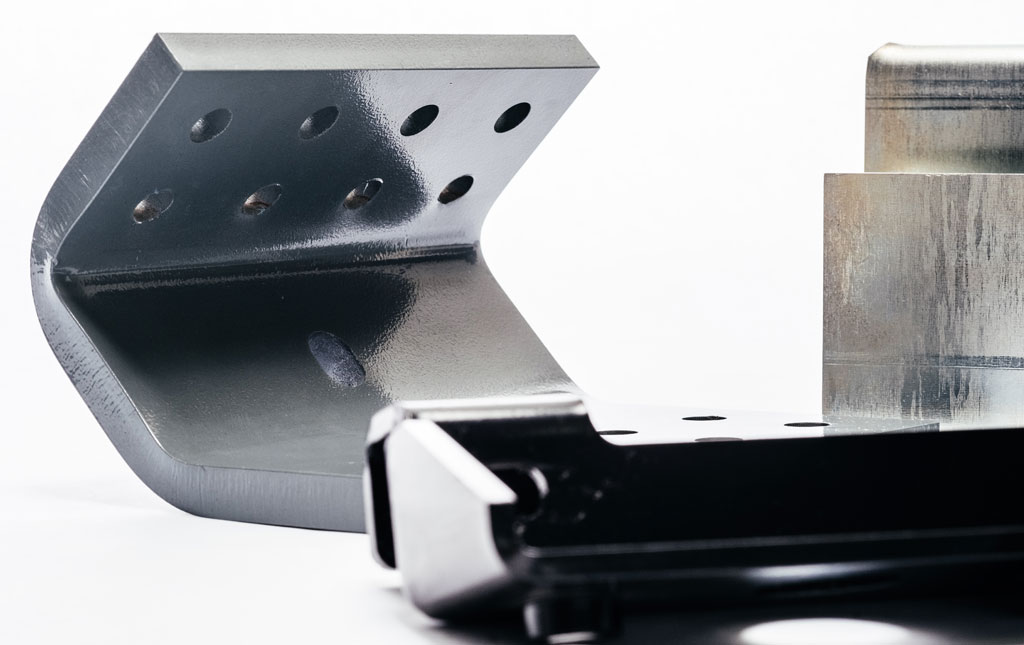

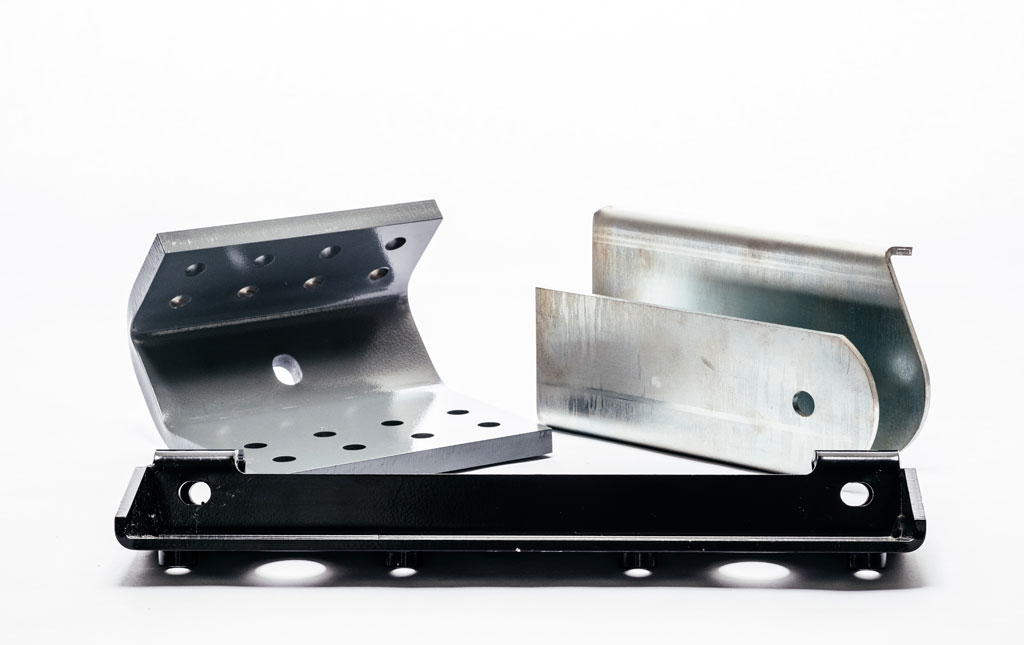

When this first became an issue, the customer called American Engineering & Metalworking to see if we could bail them out. We requested a CAD model of the part, ascertained that we could make it quickly, and had it to them within 24 hours.

Not content to assist the client just once, we proposed a long-term solution and stocking agreement. Now, when the situation arises, we make multiples of the missing part and keep some on hand at our site in case the client is in the predicament again. This small dose of preventative medicine turns potential crises into easy fixes.