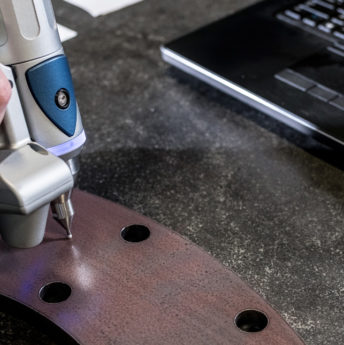

Introducing the FaroArm Measuring System

American Engineering & Metalworking is proud to use the FaroArm Measuring System, coupled with Polyworks Software.

These revolutionary tools maximize the benefits of 3D technologies, allowing AEM to collect more precise measurements as we fabricate your products. From part and tool design and prototyping down to final inspection of assembled products, we can evaluate our work at every step of the process, catching any problems before they occur.

We can also use data collected by the FaroArm to help you design more precise components, eliminating assembly problems, enhancing quality, and reducing costs from day one. After day one, the FaroArm can also tell us whether or not parts are meeting the specifications customers set forth.

Applications

- Helps provide First Article Inspection (FAI) in whatever format you need

- Helps provide Production Part Approval Process (PPAP) to make sure your requirements are being met before production

- Full dimensional analysis of even the most complicated parts

- CAD-Based Inspection that quickly identifies deviations from nominal CAD data

- Rapid, accurate and detailed 3D measurement of complex parts and assemblies when contact inspection is not practical

- Inspection of incoming parts from suppliers to verify and confirm components and products are within specifications

- Measure and inspect the part or assembly as it is being produced, in-line, in-process and on-machine

- Verify that machines and tools are operating within specifications in order to consistently produce conforming parts

- Tool Building & Setup: precise and accurate tools are required for precise, accurate and efficient production.

- Reverse engineer and create fully surfaced CAD models of design concepts or replacement parts

SPECIFICATIONS

- Maximum working volume of 130 cubic feet (3.7 cubic meters).

- Single point repeatability as close as .0009” (.024 mm).